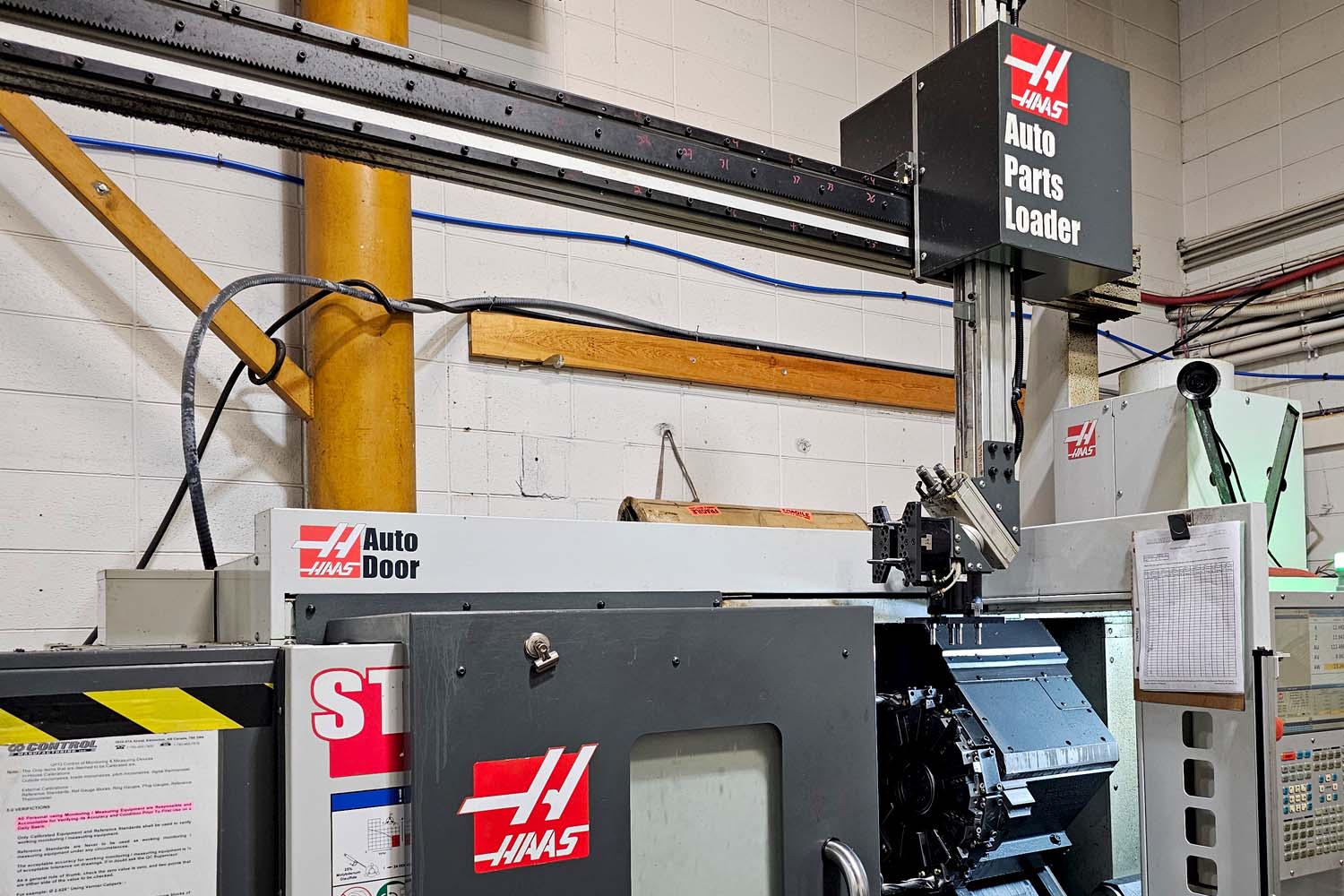

HAAS ST15 WITH APL (Automated Part Loading)

FULL CNC. 20 H.P. 2.500 THROUGH SPINDLE – 14” MAXIMUM SWING 16” BED LENGTH.

A compact, high-performance CNC turning center paired with a factory-integrated automation system designed to boost throughput and reduce operator intervention. Ideal for high-volume production of small to medium-sized parts where consistent cycle times and around-the-clock operation can significantly improve productivity.

Key Features:

- CNC Turning: Rigid 2-axis lathe with 2.5″ bar capacity and a maximum cutting diameter of about 16″.

- High-Torque Spindle: 15 HP vector drive for cutting a wide range of materials, from aluminum to stainless steel.

- Compact Footprint: Efficient layout ideal for smaller shop spaces without sacrificing capacity.

- Integrated APL: Robot-style arm with a storage table that automatically loads and unloads parts, reducing downtime between cycles.

- Ease of Use: Simple setup with Haas APL interface directly on the control, with templates for fast programming..